The Best Strategy To Use For Hon Hai Precisions

Wiki Article

The Of Lean Manufacturing

Table of ContentsMfg Things To Know Before You Get ThisFascination About ManufacturingA Biased View of Plastic Manufacturing5 Easy Facts About Plastic Manufacturing ShownThe Basic Principles Of Additive Manufacturing The 5-Minute Rule for Manufacturing Industries

The text on this web page is an example from our full White Paper 'Injection Moulding for Purchasers' - * Sample text * - for full guide click the download switch above! Intro This overview is meant for individuals that are looking to resource plastic mouldings. It gives a much needed understanding right into all that is involved with developing plastic parts, from the mould tool required to the moulding process itself.If you wish to check out further, the guide covers kinds of mould devices, as well as special completing procedures such as colours & plating. Words that are highlighted can be located in the glossary in the appendix ... Part I: Moulding: The Essentials The Benefits of Injection Moulding Plastic shot moulding is a really exact procedure that uses numerous advantages over other plastic processing techniques.

Precision is best for very complex parts. Compared to other techniques, moulding permits you to include more features at really tiny tolerances. Have an appearance at the picture to the. You can hold this moulding in the palm of your hand and also it has bosses, ribs, steel inserts, side cores and also openings, made with a moving shut off function in the mould tool.

A Biased View of Lean Manufacturing

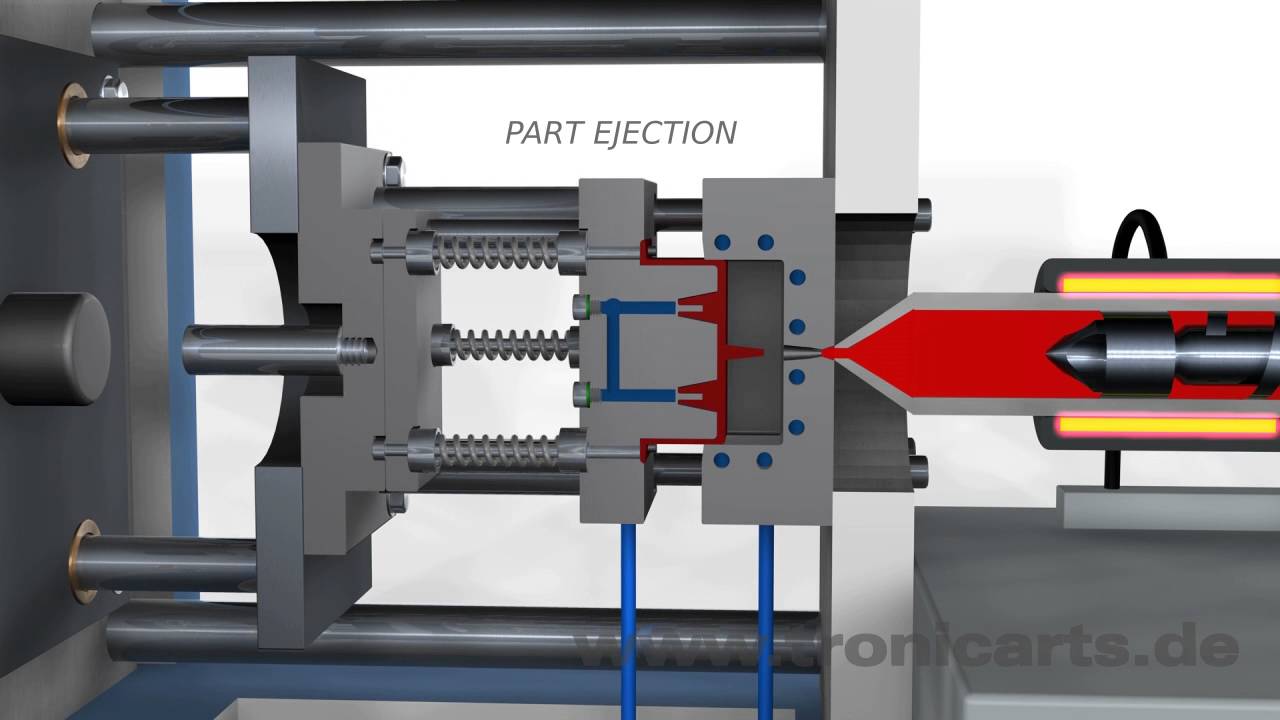

from material feed & melting; material injectionProduct cooling time cooling down ejection as well as the re-closing of the mould tool ready device all set next cycleFollowing Draft angles - The walls of a moulded part ought to be a little tapered in the instructions in which the component is ejected from the mould device, to enable the part to be expelled quickly.

Ejector stroke - The pressing out of ejector pins to eject the moulded component from the mould tool. Ejector stroke speed, size and timing needs to be thoroughly regulated to stop damage to the ejectors and mould device, yet at the same time make the moulding cycle as short as possible.

The Main Principles Of Hon Hai Precision

Ribs - When a plastic component has thin walls, ribs are included to the layout to make the slim walls more powerful Side cores - Side action which produces an attribute on a moulded part, at an opposing angle to the regular opening instructions of the mould tool. hon hai precision. The side core requires to be able to retract as the plastic part can not be ejected or else.

Wall surfaces - The sides of a moulded part The message on this web page is a sample from our complete White Paper 'Shot Moulding for Customers'.

Shot moulding is extensively utilized for manufacturing a variety of parts, from the tiniest parts to whole body panels of cars and trucks. Shot moulding utilizes a special-purpose maker that has three parts: the injection device, the mould and the clamp.

Oem for Beginners

Process attributes [modify] Shot moulding uses a ram or screw-type bettor to compel liquified plastic or rubber product into a mould dental caries; this solidifies into a shape that has actually adapted the shape of the mould. It is most generally utilized to process both polycarbonate and thermosetting polymers, with use this link the volume use the previous being significantly higher.: 13 Thermoplastics prevail due to features that make them extremely appropriate for injection moulding, such as simplicity of recycling, versatility for a variety of applications,: 89 and capability to soften and move on heating.In numerous cavity moulds, each dental caries can be similar and also develop the exact same components or can be special as well as develop multiple different geometries during a solitary cycle.

The screw provides the raw material ahead, mixes and also homogenises the thermal and also viscous distributions of the polymer, as well as lowers the why not try these out called for home heating time by mechanically shearing the material and also including a substantial amount of frictional home heating to the polymer. The product feeds onward via a check valve and also accumulates at the front of the screw right into a quantity referred to as a shot. When sufficient product has collected, the material is compelled at high pressure and also rate into the part creating cavity. The precise amount of contraction is a function of the resin being used, as well as can be reasonably foreseeable. To avoid spikes in stress, the procedure typically makes use of a transfer placement matching to a 9598% full tooth cavity where the screw shifts from a continuous rate to a continuous stress control.

Unknown Facts About Mfg

Once the screw gets to the transfer placement the packing pressure is used, which finishes mould dental filling and makes up for thermal shrinkage, which is rather high for thermoplastics family member to many other materials. The packing pressure is applied till the gateway (tooth cavity entrance) strengthens. As a result of its small dimension, eviction is normally the first location to solidify via its entire thickness.: 16 Once the gate strengthens, say goodbye to product can go into the tooth cavity; accordingly, the you can look here screw reciprocates as well as acquires material for the next cycle while the product within the mould cools to ensure that it can be expelled and be dimensionally stable.Report this wiki page